Note

Go to the end to download the full example code.

Basic sandwich panel example#

This example defines a composite lay-up for a sandwich panel using PyACP. It only shows the PyACP part of the setup. For a complete composite analysis, see Basic PyACP workflow example.

Import the standard library and third-party dependencies.

import pathlib

import tempfile

Import the PyACP dependencies.

from ansys.acp.core import (

ACPWorkflow,

FabricWithAngle,

Lamina,

PlyType,

get_directions_plotter,

launch_acp,

print_model,

)

from ansys.acp.core.example_helpers import ExampleKeys, get_example_file

from ansys.acp.core.material_property_sets import ConstantEngineeringConstants, ConstantStrainLimits

Start ACP and load the model#

Get the example file from the server.

tempdir = tempfile.TemporaryDirectory()

WORKING_DIR = pathlib.Path(tempdir.name)

input_file = get_example_file(ExampleKeys.BASIC_FLAT_PLATE_DAT, WORKING_DIR)

Launch the PyACP server and connect to it.

acp = launch_acp()

Define the input file and instantiate an ACPWorkflow instance.

The ACPWorkflow class provides convenience methods that simplify file handling.

It automatically creates a model based on the input file.

workflow = ACPWorkflow.from_cdb_or_dat_file(

acp=acp,

cdb_or_dat_file_path=input_file,

local_working_directory=WORKING_DIR,

)

model = workflow.model

print(workflow.working_directory.path)

print(model.unit_system)

/tmp/tmpo3arvw70

mks

Visualize the loaded mesh.

Create the sandwich materials#

Create the UD material and its corresponding fabric.

engineering_constants_ud = ConstantEngineeringConstants.from_orthotropic_constants(

E1=5e10, E2=1e10, E3=1e10, nu12=0.28, nu13=0.28, nu23=0.3, G12=5e9, G23=4e9, G31=4e9

)

strain_limit = 0.01

strain_limits = ConstantStrainLimits.from_orthotropic_constants(

eXc=-strain_limit,

eYc=-strain_limit,

eZc=-strain_limit,

eXt=strain_limit,

eYt=strain_limit,

eZt=strain_limit,

eSxy=strain_limit,

eSyz=strain_limit,

eSxz=strain_limit,

)

ud_material = model.create_material(

name="UD",

ply_type=PlyType.REGULAR,

engineering_constants=engineering_constants_ud,

strain_limits=strain_limits,

)

ud_fabric = model.create_fabric(name="UD", material=ud_material, thickness=0.002)

Create a multi-axial stackup and a sublaminate. Stackups and sublaminates help quickly build repeating laminates.

biax_carbon_ud = model.create_stackup(

name="Biax_Carbon_UD",

fabrics=(

FabricWithAngle(ud_fabric, -45),

FabricWithAngle(ud_fabric, 45),

),

)

sublaminate = model.create_sublaminate(

name="Sublaminate",

materials=(

Lamina(biax_carbon_ud, 0),

Lamina(ud_fabric, 90),

Lamina(biax_carbon_ud, 0),

),

)

Create the core material and its corresponding fabric.

engineering_constants_core = ConstantEngineeringConstants.from_isotropic_constants(E=8.5e7, nu=0.3)

core = model.create_material(

name="Core",

ply_type=PlyType.ISOTROPIC_HOMOGENEOUS_CORE,

engineering_constants=engineering_constants_core,

strain_limits=strain_limits,

)

core_fabric = model.create_fabric(name="core", material=ud_material, thickness=0.015)

Create the Lay-up#

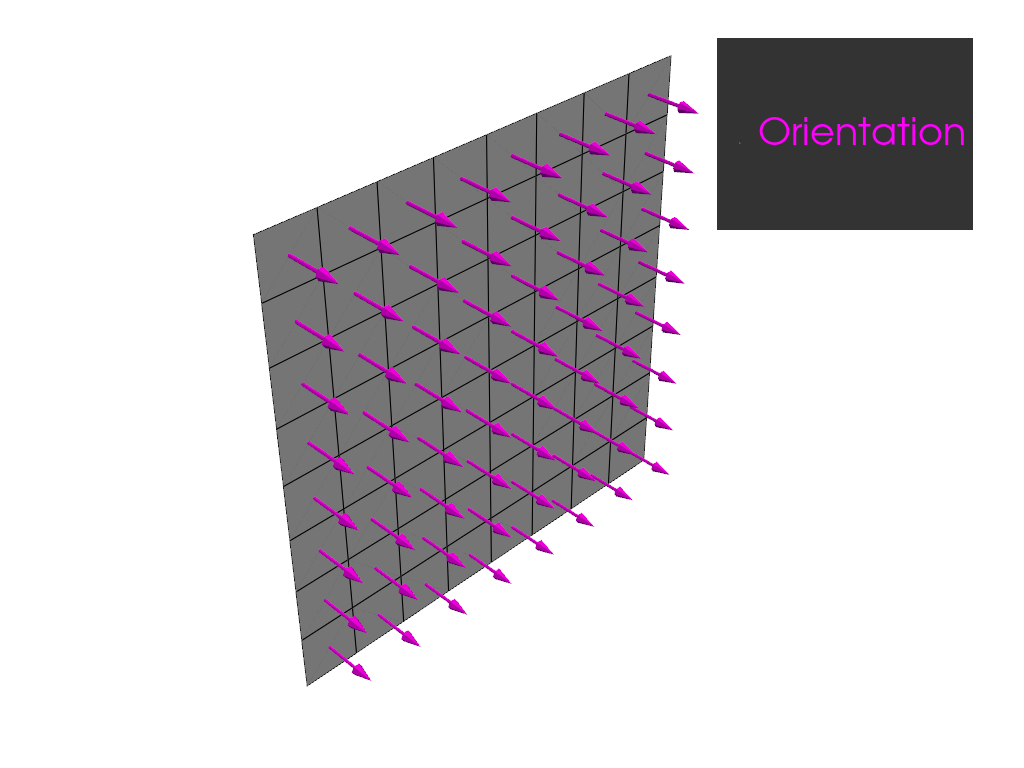

Define a rosette and oriented selection set. Plot the orientations.

rosette = model.create_rosette(origin=(0.0, 0.0, 0.0), dir1=(1.0, 0.0, 0.0), dir2=(0.0, 1.0, 0.0))

oss = model.create_oriented_selection_set(

name="oss",

orientation_point=(0.0, 0.0, 0.0),

orientation_direction=(0.0, 1.0, 0),

element_sets=[model.element_sets["All_Elements"]],

rosettes=[rosette],

)

model.update()

plotter = get_directions_plotter(model=model, components=[oss.elemental_data.orientation])

plotter.show()

Create the modeling plies which define the lay-up of the sandwich panel.

modeling_group = model.create_modeling_group(name="modeling_group")

bottom_ply = modeling_group.create_modeling_ply(

name="bottom_ply",

ply_angle=0,

ply_material=sublaminate,

oriented_selection_sets=[oss],

)

core_ply = modeling_group.create_modeling_ply(

name="core_ply",

ply_angle=0,

ply_material=core_fabric,

oriented_selection_sets=[oss],

)

top_ply = modeling_group.create_modeling_ply(

name="top_ply",

ply_angle=90,

ply_material=ud_fabric,

oriented_selection_sets=[oss],

number_of_layers=3,

)

Update and print the model.

model.update()

print_model(workflow.model)

Model

Material Data

Materials

1

UD

Core

Fabrics

UD

core

Stackups

Biax_Carbon_UD

Sublaminates

Sublaminate

Element Sets

All_Elements

Edge Sets

_FIXEDSU

Geometry

Rosettes

12

Rosette

Lookup Tables

Selection Rules

Oriented Selection Sets

oss

Modeling Groups

modeling_group

bottom_ply

ProductionPly

P1L1__bottom_ply

P1L2__bottom_ply

ProductionPly.2

P2L1__bottom_ply

ProductionPly.3

P3L1__bottom_ply

P3L2__bottom_ply

core_ply

ProductionPly.4

P1L1__core_ply

top_ply

ProductionPly.5

P1L1__top_ply

ProductionPly.6

P2L1__top_ply

ProductionPly.7

P3L1__top_ply

Total running time of the script: (0 minutes 7.936 seconds)