create_modeling_ply#

- ModelingGroup.create_modeling_ply(*, name='ModelingPly', ply_material=None, oriented_selection_sets=(), ply_angle=0.0, number_of_layers=1, active=True, global_ply_nr=0, selection_rules=(), draping_type='no_draping', draping_seed_point=(0.0, 0.0, 0.0), auto_draping_direction=True, draping_direction=(1.0, 0.0, 0.0), use_default_draping_mesh_size=True, draping_mesh_size=0.0, draping_thickness_correction=True, draping_angle_1_field=None, draping_angle_2_field=None, thickness_type='nominal', thickness_geometry=None, thickness_field=None, thickness_field_type='absolute_values', taper_edges=())#

Instantiate a Modeling Ply.

- Parameters:

name (str) – The name of the Modeling Ply

ply_material (Fabric | Stackup | SubLaminate | None) – The material (fabric, stackup or sub-laminate) of the ply.

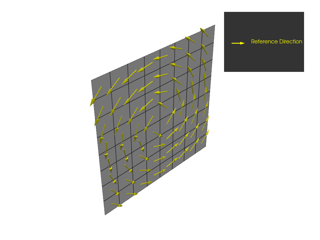

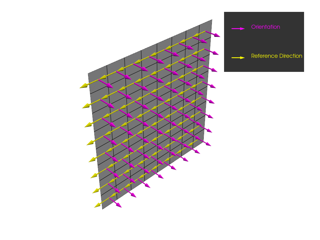

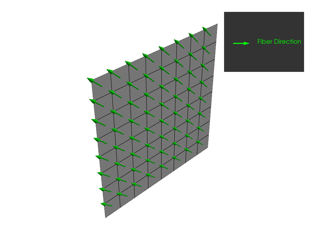

ply_angle (float) – Design angle between the reference direction and the ply fiber direction.

number_of_layers (int) – Number of times the plies are generated.

active (bool) – Inactive plies are ignored in ACP and the downstream analysis.

global_ply_nr (int) – Defines the global ply order.

selection_rules (Iterable[LinkedSelectionRule]) – Selection Rules which may limit the extent of the ply.

draping_type (DrapingType) – Chooses between different draping formulations.

draping_seed_point (tuple[float, float, float]) – Starting point of the draping algorithm.

auto_draping_direction (bool) –

- If

True, the fiber direction of the production ply at the draping seed point is used as draping direction.

- If

draping_direction (tuple[float, float, float]) – Set the primary draping direction for the draping algorithm. Only used if

auto_draping_directionisFalse.use_default_draping_mesh_size (bool) – Whether to use the average element size of the shell mesh for the draping.

draping_mesh_size (float) – Defines the mesh size for the draping algorithm. If set to

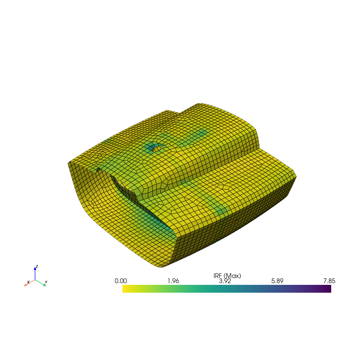

-1., the mesh size is automatically determined based on the average element size.draping_thickness_correction (bool) – Enables the thickness correction of draped plies based on the draping shear angle.

draping_angle_1_field (LookUpTable1DColumn | LookUpTable3DColumn | None) – Correction angle between the fiber and draped fiber directions, in degree.

draping_angle_2_field (LookUpTable1DColumn | LookUpTable3DColumn | None) – Correction angle between the transverse and draped transverse directions, in degree. Optional, uses the same values as

draping_angle_1_field(no shear) by default.thickness_type (ThicknessType) – Choose between

ThicknessType.FROM_GEOMETRYorThicknessType.FROM_TABLEto define a ply with variable thickness. The default value isThicknessType.NOMINAL, which means the ply thickness is constant and determined by the thickness of the ply material.thickness_geometry (VirtualGeometry | None) – Defines the geometry used to determine the ply thickness. Only applies if

thickness_typeisThicknessType.FROM_GEOMETRY.thickness_field (LookUpTable1DColumn | LookUpTable3DColumn | None) – Defines the look-up table column used to determine the ply thickness. Only applies if

thickness_typeisThicknessType.FROM_TABLE.thickness_field_type (ThicknessFieldType) – If

thickness_typeisThicknessType.FROM_TABLE, this parameter determines how the thickness values are interpreted. They can be either absolute values (ThicknessFieldType.ABSOLUTE_VALUES) or relative values (ThicknessFieldType.RELATIVE_SCALING_FACTOR).taper_edges (Iterable[TaperEdge]) – Defines the taper edges of the ply.

- Return type:

Added in ACP server version 24.2.