Note

Go to the end to download the full example code.

Advanced PyMAPDL workflow#

This example shows how to define a composite lay-up with PyACP, solve the resulting model with PyMAPDL, and run a failure analysis with PyDPF - Composites.

Begin with an MAPDL CDB file that contains the mesh, material data, and

boundary conditions. Import the file to PyACP to define the lay-up, and then export the

resulting model to PyMAPDL. Once the results are available, the RST file is loaded in

PyDPF - Composites for postprocessing. The additional input files (material.xml

and ACPCompositeDefinitions.h5) can also be stored with PyACP and passed to PyDPF - Composites.

Import modules and start ACP#

Import the standard library and third-party dependencies.

import pathlib

import tempfile

import pyvista

Import the Ansys libraries.

import ansys.acp.core as pyacp

from ansys.acp.core.extras import set_plot_theme

Set the plot theme for the example. This is optional, and ensures that you get the same plot style (theme, color map, etc.) as in the online documentation.

set_plot_theme()

Launch the PyACP server and connect to it.

acp = pyacp.launch_acp()

Get example input files#

Create a temporary working directory, and download the example input files to this directory.

working_dir = tempfile.TemporaryDirectory()

working_dir_path = pathlib.Path(working_dir.name)

input_file = pyacp.extras.example_helpers.get_example_file(

pyacp.extras.example_helpers.ExampleKeys.CLASS40_CDB, working_dir_path

)

Load mesh and materials from CDB file#

Load the CDB file into PyACP and set the unit system.

model = acp.import_model(path=input_file, format="ansys:cdb", unit_system=pyacp.UnitSystemType.MKS)

model

<Model with name 'ACP Lay-up Model'>

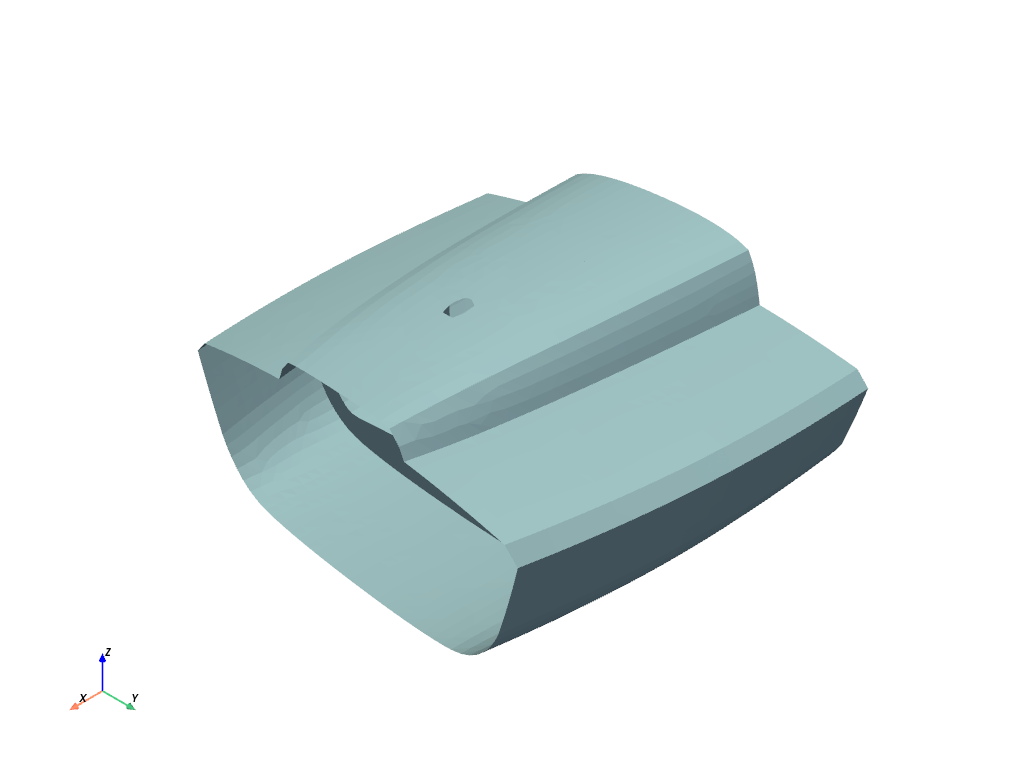

Visualize the loaded mesh.

Build Composite Lay-up#

Create the model (MKS unit system).

Materials#

mat_corecell_81kg = model.materials["1"]

mat_corecell_81kg.name = "Core Cell 81kg"

mat_corecell_81kg.ply_type = "isotropic_homogeneous_core"

mat_corecell_103kg = model.materials["2"]

mat_corecell_103kg.name = "Core Cell 103kg"

mat_corecell_103kg.ply_type = "isotropic_homogeneous_core"

mat_eglass_ud = model.materials["3"]

mat_eglass_ud.name = "E-Glass (uni-directional)"

mat_eglass_ud.ply_type = "regular"

Fabrics#

corecell_81kg_5mm = model.create_fabric(

name="Corecell 81kg", thickness=0.005, material=mat_corecell_81kg

)

corecell_103kg_10mm = model.create_fabric(

name="Corecell 103kg", thickness=0.01, material=mat_corecell_103kg

)

eglass_ud_02mm = model.create_fabric(name="eglass UD", thickness=0.0002, material=mat_eglass_ud)

Rosettes#

ros_deck = model.create_rosette(name="ros_deck", origin=(-5.9334, -0.0481, 1.693))

ros_hull = model.create_rosette(name="ros_hull", origin=(-5.3711, -0.0506, -0.2551))

ros_bulkhead = model.create_rosette(

name="ros_bulkhead", origin=(-5.622, 0.0022, 0.0847), dir1=(0.0, 1.0, 0.0), dir2=(0.0, 0.0, 1.0)

)

ros_keeltower = model.create_rosette(

name="ros_keeltower", origin=(-6.0699, -0.0502, 0.623), dir1=(0.0, 0.0, 1.0)

)

Oriented Selection Sets#

Note that the element sets are imported from the initial mesh (CBD file).

oss_deck = model.create_oriented_selection_set(

name="oss_deck",

orientation_point=(-5.3806, -0.0016, 1.6449),

orientation_direction=(0.0, 0.0, -1.0),

element_sets=[model.element_sets["DECK"]],

rosettes=[ros_deck],

)

oss_hull = model.create_oriented_selection_set(

name="oss_hull",

orientation_point=(-5.12, 0.1949, -0.2487),

orientation_direction=(0.0, 0.0, 1.0),

element_sets=[model.element_sets["HULL_ALL"]],

rosettes=[ros_hull],

)

oss_bulkhead = model.create_oriented_selection_set(

name="oss_bulkhead",

orientation_point=(-5.622, -0.0465, -0.094),

orientation_direction=(1.0, 0.0, 0.0),

element_sets=[model.element_sets["BULKHEAD_ALL"]],

rosettes=[ros_bulkhead],

)

esets = [

model.element_sets["KEELTOWER_AFT"],

model.element_sets["KEELTOWER_FRONT"],

model.element_sets["KEELTOWER_PORT"],

model.element_sets["KEELTOWER_STB"],

]

oss_keeltower = model.create_oriented_selection_set(

name="oss_keeltower",

orientation_point=(-6.1019, 0.0001, 1.162),

orientation_direction=(-1.0, 0.0, 0.0),

element_sets=esets,

rosettes=[ros_keeltower],

)

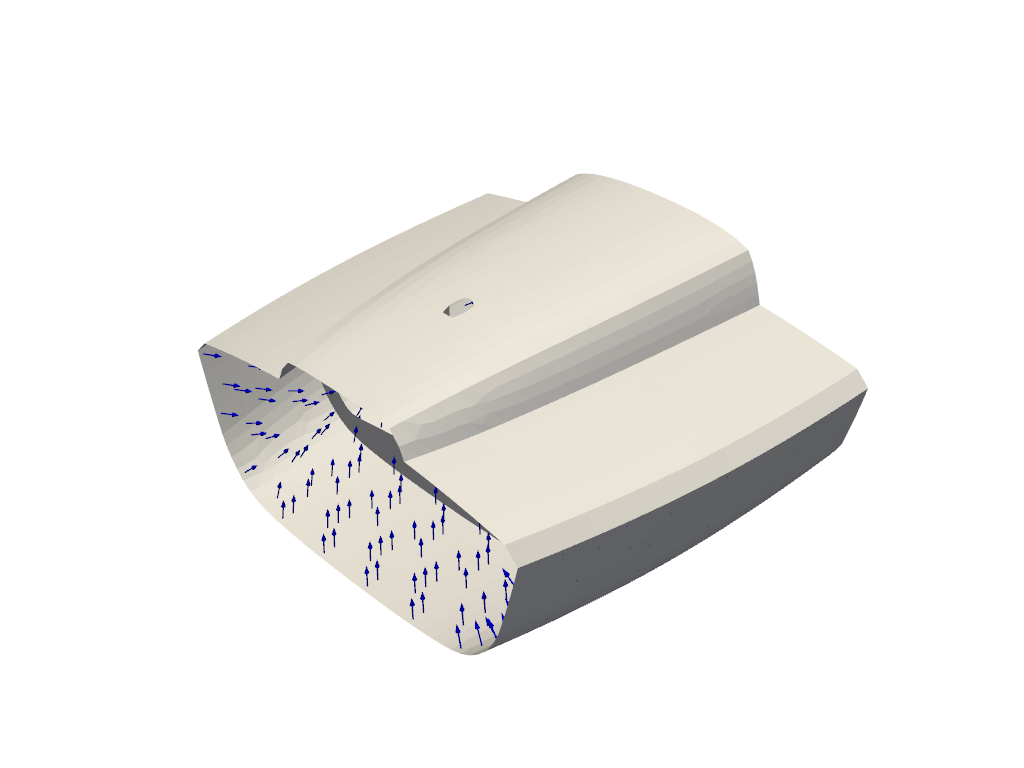

Show the orientations on the hull oriented selection set (OSS).

Note that the model must be updated before the orientations are available.

model.update()

plotter = pyvista.Plotter()

plotter.add_mesh(model.mesh.to_pyvista(), color="white")

orientation = oss_hull.elemental_data.orientation

assert orientation is not None

plotter.add_mesh(

orientation.get_pyvista_glyphs(mesh=model.mesh, factor=0.2, culling_factor=5),

color="blue",

)

plotter.show()

Modeling Plies#

Define plies for the hull, deck, and bulkhead.

angles = [-90.0, -60.0, -45.0 - 30.0, 0.0, 0.0, 30.0, 45.0, 60.0, 90.0]

for mg_name in ["hull", "deck", "bulkhead"]:

mg = model.create_modeling_group(name=mg_name)

oss_list = [model.oriented_selection_sets["oss_" + mg_name]]

for angle in angles:

add_ply(mg, "eglass_ud_02mm_" + str(angle), eglass_ud_02mm, angle, oss_list)

add_ply(mg, "corecell_103kg_10mm", corecell_103kg_10mm, 0.0, oss_list)

for angle in angles:

add_ply(mg, "eglass_ud_02mm_" + str(angle), eglass_ud_02mm, angle, oss_list)

Add plies to the keeltower.

mg = model.create_modeling_group(name="keeltower")

oss_list = [model.oriented_selection_sets["oss_keeltower"]]

for angle in angles:

add_ply(mg, "eglass_ud_02mm_" + str(angle), eglass_ud_02mm, angle, oss_list)

add_ply(mg, "corecell_81kg_5mm", corecell_81kg_5mm, 0.0, oss_list)

for angle in angles:

add_ply(mg, "eglass_ud_02mm_" + str(angle), eglass_ud_02mm, angle, oss_list)

Inspect the number of modeling groups and plies.

print(len(model.modeling_groups))

print(len(model.modeling_groups["hull"].modeling_plies))

print(len(model.modeling_groups["deck"].modeling_plies))

print(len(model.modeling_groups["bulkhead"].modeling_plies))

print(len(model.modeling_groups["keeltower"].modeling_plies))

4

19

19

19

19

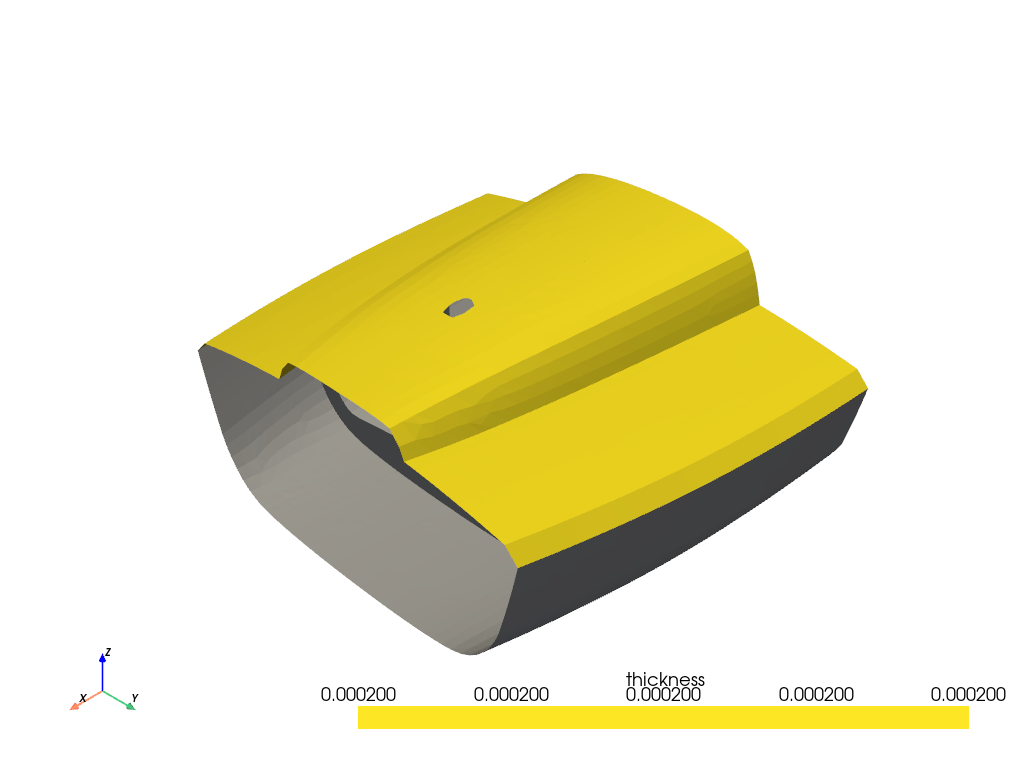

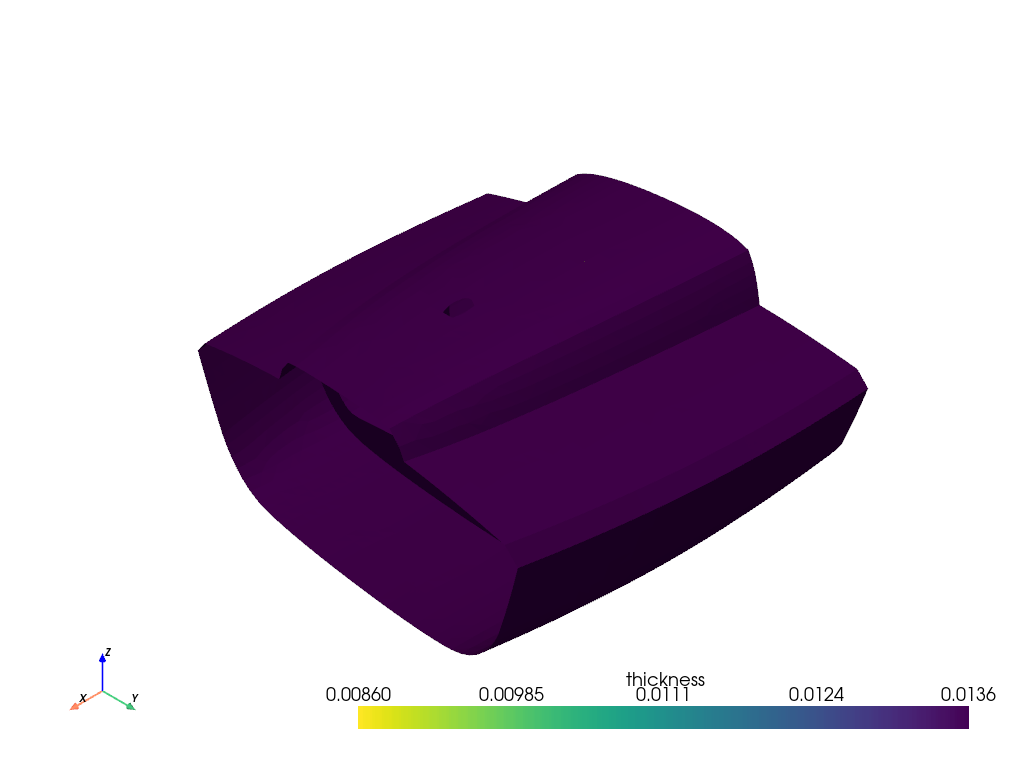

Show the thickness of one of the plies.

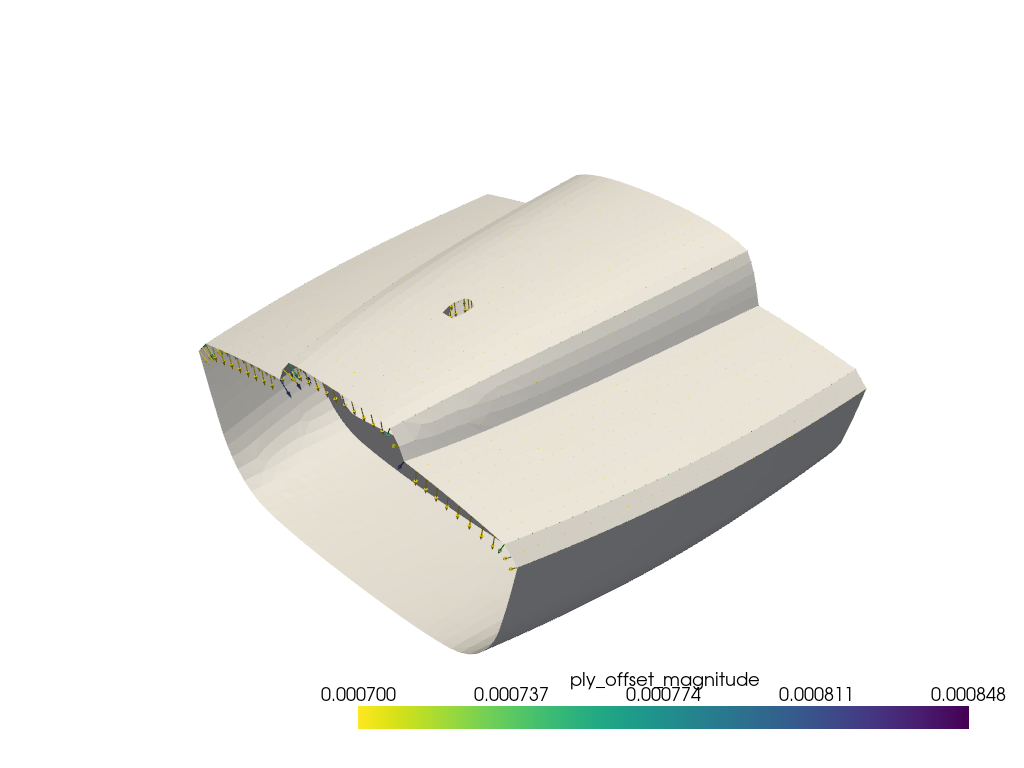

Show the ply offsets that are scaled by a factor of 200.

plotter = pyvista.Plotter()

plotter.add_mesh(model.mesh.to_pyvista(), color="white")

ply_offset = modeling_ply.nodal_data.ply_offset

assert ply_offset is not None

plotter.add_mesh(

ply_offset.get_pyvista_glyphs(mesh=model.mesh, factor=200),

)

plotter.show()

Show the thickness of the entire lay-up.

Write out ACP Model#

acph5_filename = "class40.acph5"

cdb_filename_out = "class40_analysis_model.cdb"

composite_definition_h5_filename = "ACPCompositeDefinitions.h5"

matml_filename = "materials.xml"

Update and save the ACP model.

model.update()

model.save(working_dir_path / acph5_filename, save_cache=True)

Save the model as a CDB file for solving with PyMAPDL.

model.export_analysis_model(working_dir_path / cdb_filename_out)

# Export the shell lay-up and material file for PyDPF - Composites.

model.export_shell_composite_definitions(working_dir_path / composite_definition_h5_filename)

model.export_materials(working_dir_path / matml_filename)

Solve with PyMAPDL#

Import PyMAPDL and connect to its server.

from ansys.mapdl.core import launch_mapdl

mapdl = launch_mapdl()

mapdl.clear()

Load the CDB file into PyMAPDL.

mapdl.input(str(working_dir_path / cdb_filename_out))

'\n /INPUT FILE= LINE= 0\n ANSYS RELEASE 11.0 UP20070125 16:39:41 03/10/2009\n *****MAPDL VERIFICATION RUN ONLY*****\n DO NOT USE RESULTS FOR PRODUCTION\n\n ***** MAPDL ANALYSIS DEFINITION (PREP7) *****\n\n\n ***** ROUTINE COMPLETED ***** ELAPSED TIME = 0.000\n\n\n'

Solve the model.

mapdl.allsel()

mapdl.slashsolu()

mapdl.solve()

***** MAPDL SOLVE COMMAND *****

*** NOTE *** ELAPSED TIME = 0.000 TIME= 00:00:00

There is no title defined for this analysis.

*** SELECTION OF ELEMENT TECHNOLOGIES FOR APPLICABLE ELEMENTS ***

---GIVE SUGGESTIONS ONLY---

ELEMENT TYPE 1 IS SHELL181. IT IS ASSOCIATED WITH ELASTOPLASTIC

MATERIALS ONLY. KEYOPT(8) IS ALREADY SET AS SUGGESTED. KEYOPT(3)=2

IS SUGGESTED FOR HIGHER ACCURACY OF MEMBRANE STRESSES; OTHERWISE,

KEYOPT(3)=0 IS SUGGESTED.

ELEMENT TYPE 2 IS BEAM188 . KEYOPT(1)=1 IS SUGGESTED FOR NON-CIRCULAR CROSS

SECTIONS AND KEYOPT(3)=2 IS ALWAYS SUGGESTED.

ELEMENT TYPE 2 IS BEAM188 . KEYOPT(15) IS ALREADY SET AS SUGGESTED.

ELEMENT TYPE 3 IS SHELL181. IT IS ASSOCIATED WITH ELASTOPLASTIC

MATERIALS ONLY. KEYOPT(8) IS ALREADY SET AS SUGGESTED. KEYOPT(3)=2

IS SUGGESTED FOR HIGHER ACCURACY OF MEMBRANE STRESSES; OTHERWISE,

KEYOPT(3)=0 IS SUGGESTED.

*****MAPDL VERIFICATION RUN ONLY*****

DO NOT USE RESULTS FOR PRODUCTION

S O L U T I O N O P T I O N S

PROBLEM DIMENSIONALITY. . . . . . . . . . . . .3-D

DEGREES OF FREEDOM. . . . . . UX UY UZ ROTX ROTY ROTZ

ANALYSIS TYPE . . . . . . . . . . . . . . . . .STATIC (STEADY-STATE)

GLOBALLY ASSEMBLED MATRIX . . . . . . . . . . .SYMMETRIC

*** NOTE *** ELAPSED TIME = 0.000 TIME= 00:00:00

Poisson's ratio PR input has been converted to NU input.

*** NOTE *** ELAPSED TIME = 0.000 TIME= 00:00:00

Present time 0 is less than or equal to the previous time. Time will

default to 1.

*** NOTE *** ELAPSED TIME = 0.000 TIME= 00:00:00

The conditions for direct assembly have been met. No .emat or .erot

files will be produced.

L O A D S T E P O P T I O N S

LOAD STEP NUMBER. . . . . . . . . . . . . . . . 1

TIME AT END OF THE LOAD STEP. . . . . . . . . . 1.0000

NUMBER OF SUBSTEPS. . . . . . . . . . . . . . . 1

STEP CHANGE BOUNDARY CONDITIONS . . . . . . . . NO

PRINT OUTPUT CONTROLS . . . . . . . . . . . . .NO PRINTOUT

DATABASE OUTPUT CONTROLS. . . . . . . . . . . .ALL DATA WRITTEN

FOR THE LAST SUBSTEP

*** NOTE *** ELAPSED TIME = 0.000 TIME= 00:00:00

Predictor is ON by default for structural elements with rotational

degrees of freedom. Use the PRED,OFF command to turn the predictor

OFF if it adversely affects the convergence.

*********** PRECISE MASS SUMMARY ***********

TOTAL RIGID BODY MASS MATRIX ABOUT ORIGIN

Translational mass | Coupled translational/rotational mass

324.96 0.46544E-18 0.14304E-17 | -0.11582E-16 211.44 -0.36088E-02

0.46544E-18 324.96 -0.49693E-17 | -211.44 -0.96175E-17 -2015.3

0.14304E-17 -0.49693E-17 324.96 | 0.36088E-02 2015.3 0.20783E-16

------------------------------------------ | ------------------------------------------

| Rotational mass (inertia)

| 759.66 0.20436E-01 1316.9

| 0.20436E-01 13054. -0.32469E-02

| 1316.9 -0.32469E-02 13218.

TOTAL MASS = 324.96

The mass principal axes coincide with the global Cartesian axes

CENTER OF MASS (X,Y,Z)= -6.2017 0.11105E-04 0.65067

TOTAL INERTIA ABOUT CENTER OF MASS

622.08 -0.19444E-02 5.6093

-0.19444E-02 418.20 -0.89877E-03

5.6093 -0.89877E-03 719.59

PRINCIPAL INERTIAS = 621.76 418.20 719.92

ORIENTATION VECTORS OF THE INERTIA PRINCIPAL AXES IN GLOBAL CARTESIAN

( 0.998,-0.000,-0.057) ( 0.000, 1.000, 0.000) ( 0.057,-0.000, 0.998)

*** MASS SUMMARY BY ELEMENT TYPE ***

TYPE MASS

1 322.570

2 1.65744

3 0.729815

Range of element maximum matrix coefficients in global coordinates

Maximum = 104467551 at element 0.

Minimum = 31671440.9 at element 0.

*** ELEMENT MATRIX FORMULATION TIMES

TYPE NUMBER ENAME TOTAL ELAPSED AVG ELAPSED

1 3973 SHELL181 0.0000 0.000000000

2 88 BEAM188 0.0000 0.000000000

3 22 SHELL181 0.0000 0.000000000

Elapsed Time at end of element matrix formulation = 0.

SPARSE MATRIX DIRECT SOLVER.

Number of equations = 24096, Maximum wavefront = 0

Memory available (MB) = 0.0 , Memory required (MB) = 0.0

Sparse solver maximum pivot= 0 at node 0 .

Sparse solver minimum pivot= 0 at node 0 .

Sparse solver minimum pivot in absolute value= 0 at node 0 .

*** ELEMENT RESULT CALCULATION TIMES

TYPE NUMBER ENAME TOTAL ELAPSED AVG ELAPSED

1 3973 SHELL181 0.0000 0.000000000

2 88 BEAM188 0.0000 0.000000000

3 22 SHELL181 0.0000 0.000000000

*** NODAL LOAD CALCULATION TIMES

TYPE NUMBER ENAME TOTAL ELAPSED AVG ELAPSED

1 3973 SHELL181 0.0000 0.000000000

2 88 BEAM188 0.0000 0.000000000

3 22 SHELL181 0.0000 0.000000000

*** LOAD STEP 1 SUBSTEP 1 COMPLETED. CUM ITER = 1

*** TIME = 1.00000 TIME INC = 1.00000 NEW TRIANG MATRIX

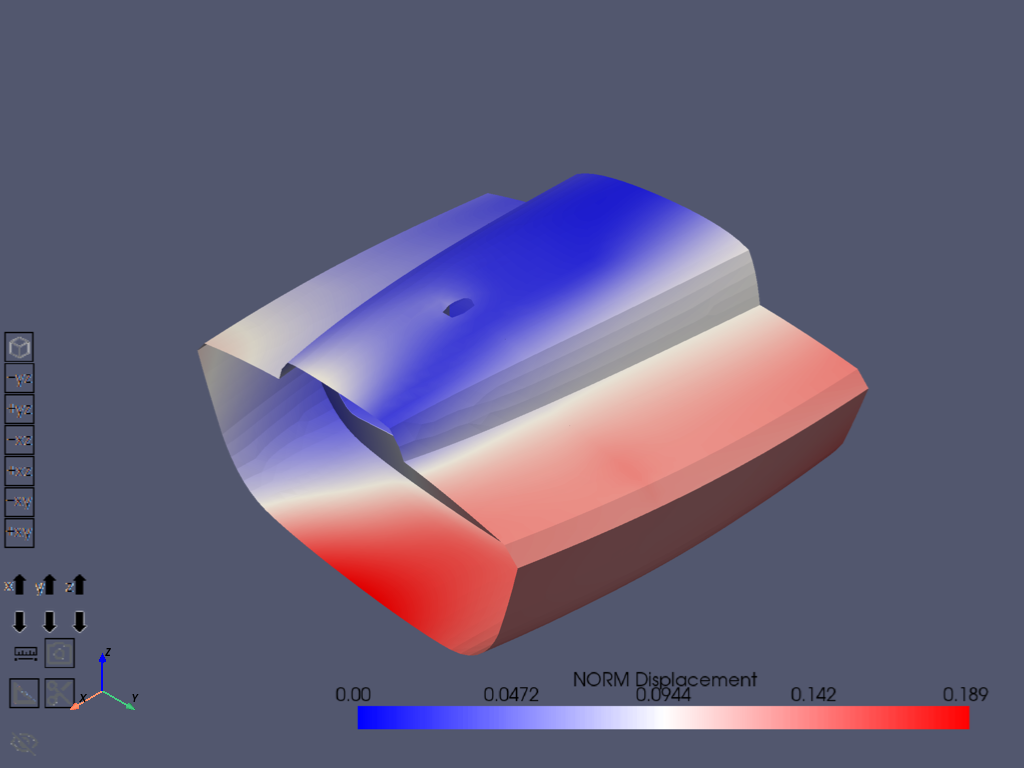

Show the displacements in postprocessing.

mapdl.post1()

mapdl.set("last")

mapdl.post_processing.plot_nodal_displacement(component="NORM")

# Download the RST file for further postprocessing.

rstfile_name = f"{mapdl.jobname}.rst"

mapdl.download(rstfile_name, working_dir_path)

[82, 87, 110]

['file.rst']

Postprocessing with PyDPF - Composites#

To postprocess the results, you must configure the imports, connect to the PyDPF - Composites server, and load its plugin.

from ansys.acp.core.dpf_integration_helpers import get_dpf_unit_system

from ansys.dpf.composites.composite_model import CompositeModel

from ansys.dpf.composites.constants import FailureOutput

from ansys.dpf.composites.data_sources import (

CompositeDefinitionFiles,

ContinuousFiberCompositesFiles,

)

from ansys.dpf.composites.failure_criteria import (

CombinedFailureCriterion,

CoreFailureCriterion,

MaxStrainCriterion,

MaxStressCriterion,

)

from ansys.dpf.composites.server_helpers import connect_to_or_start_server

Connect to the server. The connect_to_or_start_server function

automatically loads the composites plugin.

dpf_server = connect_to_or_start_server()

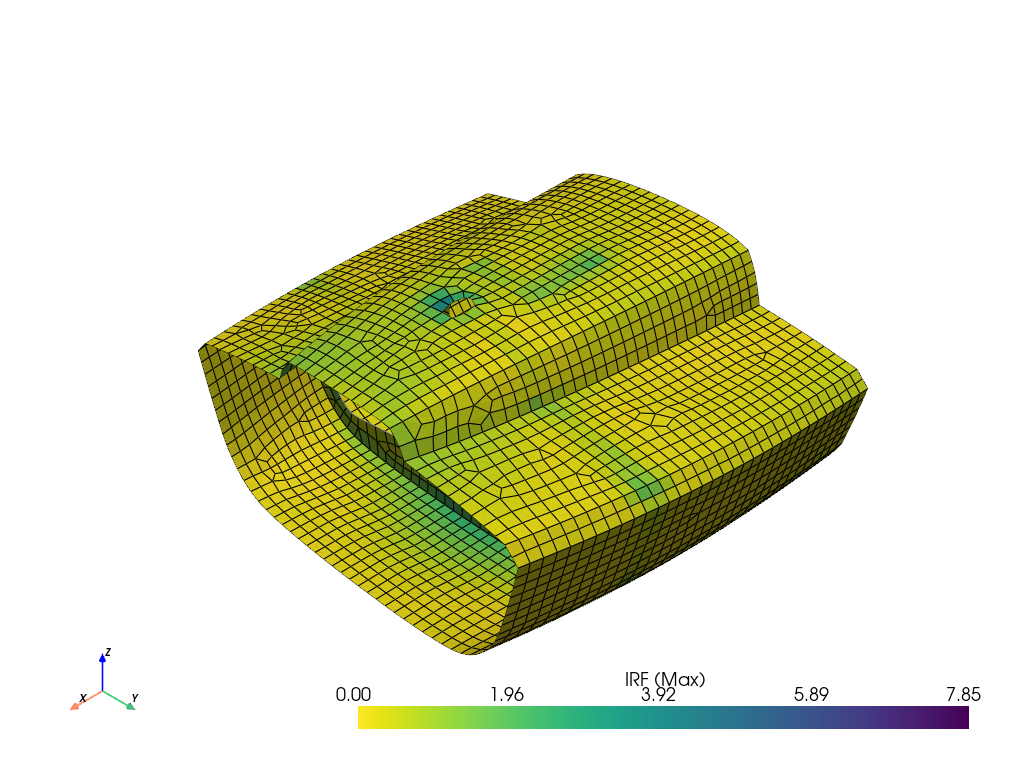

Specify the combined failure criterion.

max_strain = MaxStrainCriterion()

max_stress = MaxStressCriterion()

core_failure = CoreFailureCriterion()

cfc = CombinedFailureCriterion(

name="Combined Failure Criterion",

failure_criteria=[max_strain, max_stress, core_failure],

)

Create the composite model and configure its input.

composite_model = CompositeModel(

composite_files=ContinuousFiberCompositesFiles(

rst=working_dir_path / rstfile_name,

composite={

"shell": CompositeDefinitionFiles(

definition=working_dir_path / composite_definition_h5_filename

),

},

engineering_data=working_dir_path / matml_filename,

),

default_unit_system=get_dpf_unit_system(model.unit_system),

server=dpf_server,

)

Evaluate the failure criteria.

output_all_elements = composite_model.evaluate_failure_criteria(cfc)

Query and plot the results.

irf_field = output_all_elements.get_field({"failure_label": FailureOutput.FAILURE_VALUE})

irf_field.plot()

# Close MAPDL instance

mapdl.exit()

Total running time of the script: (0 minutes 34.617 seconds)