create_solid_model#

- Model.create_solid_model(*, name='SolidModel', active=True, element_sets=(), extrusion_method='analysis_ply_wise', max_element_thickness=1.0, ply_group_pointers=(), offset_direction_type='shell_normal', skip_elements_without_plies=False, drop_off_material=None, cut_off_material=None, delete_bad_elements=True, warping_limit=0.4, minimum_volume=0.0, drop_off_settings=<ansys.acp.core._tree_objects.solid_model.DropOffSettings object>, export_settings=<ansys.acp.core._tree_objects.solid_model.SolidModelExportSettings object>)#

Instantiate a solid model.

- Parameters:

name (str) – Name of the solid model.

active (bool) – Inactive solid models are not computed, and ignored in the analysis.

element_sets (Iterable[ElementSet | OrientedSelectionSet]) – Element sets or oriented selection sets determining the extent of the solid model.

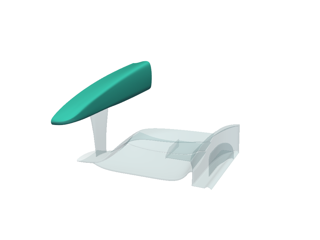

extrusion_method (ExtrusionMethod) – Determines how plies are bundled in the layered solid elements.

max_element_thickness (float) – Maximum thickness of the layered solid elements. A new element is introduced if the thickness exceeds this value. Only used if the

extrusion_methodis one ofSPECIFY_THICKNESS,MATERIAL_WISE, orSANDWICH_WISE.ply_group_pointers (Iterable[ModelingPly]) – Explicitly defines modeling plies where a new element is introduced. Only used if the

extrusion_methodisUSER_DEFINED.offset_direction_type (SolidModelOffsetDirectionType) – Determines how the extrusion direction is defined. With

SHELL_NORMAL, the normal direction of the shell is used during the entire extrusion. WithSURFACE_NORMAL, the offset direction is re-evaluated based on the surface of the solid model during the extrusion.skip_elements_without_plies (bool) – If True, elements without plies are automatically removed from the region of extrusion. This means that no drop-off elements are created for these elements.

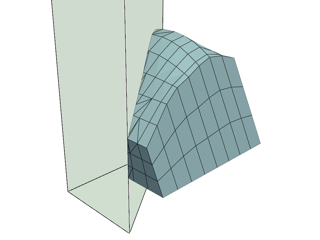

drop_off_material (Material | None) – This material is assigned to the layered solid drop-off elements if

drop_off_material_handlingis set toGLOBALin the fabric definition.cut_off_material (Material | None) – This material is assigned to the degenerated solid cut-off elements if

cut_off_material_handlingis set toGLOBALin the fabric definition.delete_bad_elements (bool) – If True, a final element check is performed to remove erroneous elements.

warping_limit (float) – Maximum allowable warping limit used in the element shape check. Elements with a warping limit exceeding this value are removed. Only used if

delete_bad_elementsis True.minimum_volume (float) – Solid elements with a volume smaller or equal to this value are removed. With the default value of

0, only inverted or zero-volume elements are removed. Only used ifdelete_bad_elementsis True.drop_off_settings (DropOffSettings) – Determines how drop-off elements are handled in the solid model extrusion.

export_settings (SolidModelExportSettings) – Defines the settings for exporting the solid model.

- Return type:

Added in ACP server version 25.1.